New control modules for trailers and swiveling tow bars according to ISO 26262

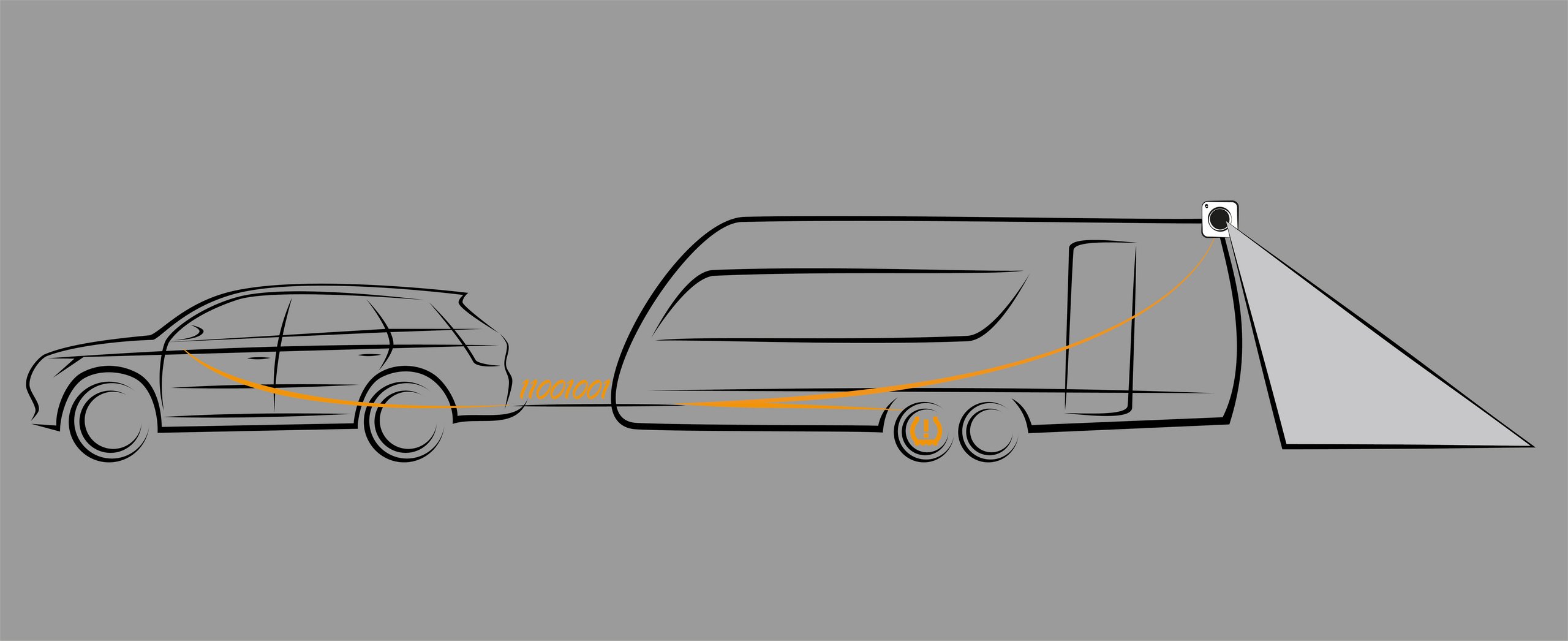

After a development phase of 18 months, Erich Jaeger could deliver the first units of a new generation of trailer control modules in late September. For the first time, the company developed modules adhering to the ISO standard for functional safety of electrical and/or electronic systems in automobiles (ISO 26262). Thus, Erich Jaeger successfully works on making its products fit for future applications – some car manufacturers already insist on their suppliers to comply to this standard when developing new products. After all, complying to the standard helps to make the complexity of modern vehicle supply systems more manageable and to make road traffic safer.

Development according to ISO 26262 and classification according to ASIL

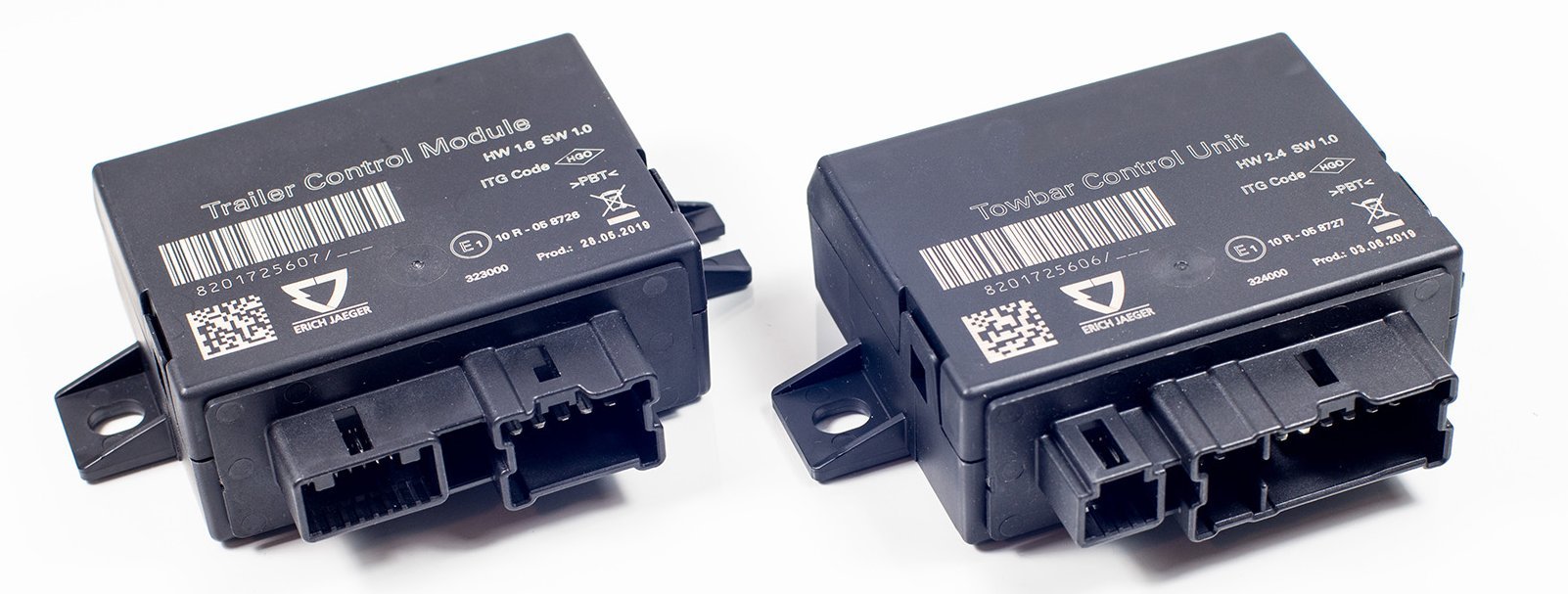

For a major car manufacturer, the Erich Jaeger engineers realized a trailer control module and a tow bar control unit for semi electric swiveling tow bars. Complying to the standard ISO 26262, both modules have been classified according to the ASIL classification describing the level of risk reduction required to prevent a specific hazard. The classification is based on a “safe state” which the system has to fall back to in case of an emergency. The trailer control module is classified as ASIL A and the tow bar control unit as ASIL B. The “safe states” which have been defined accordingly help to avoid incidences due to malfunctions of single vehicle components.

Product optimizations for housing and electronics

In addition to the standardized development, the Erich Jaeger team could implement some further optimizations: As opposed to previous modules, Erich Jaeger used PBT as material for the housing. The application of the robust material improves the structural integrity of the housing along with its resistance against environmental influences.

Unique hybrid pin header grants advantages

A newly developed and market-wide unique hybrid pin header combines common 16- and 8-pin connections of reputable manufacturers in just one component part. This results in cost advantages, and the force necessary to plug in the connection is reduced to less than 60 N compared to more than 75 N for previous modules. Both the pin header and the printed circuit board (PCB) are fixed within the housing via a guide rail and internal fixation clamps, thus minimizing the risk of damage to these components and avoiding rattling noises.

High-end electronic components

The PCB features a very low quiescence current of approx. 30 μA; this value is below the value of a maximum 100 μA required by most car manufacturers thus preserving the vehicle’s battery. For manufacturing the PCB, Erich Jaeger can access the services of its associate company Bavaria Digital Technik. The manufacturer applies cost-effective micro components and places a QR-code on PCB and housing enabling customers to retrieve information on serial no. and test documentation for every individual module. This guarantees the traceability of the control modules.