Data transmission between trailer and towing vehicle: Current practice

Existing solutions using CAN-Bus data lines

Currently, the most common solution for the exchange of data between trailer and towing vehicle is the use of CAN-Bus data cables. These cables are applied within different connector systems for heavy goods vehicle traffic and agricultural machinery and are continuously developed concerning their functionalities. However, the data transmission rate is limited to 125 Kbit/s (ISO 11992-1) or 250 Kbit/s (SAE J1939).

- Application: Heavy goods vehicle traffic

- CAN-BUS data lines corresponding to the standard protocol according to ISO 11992-2

- Transmission of data for the brake system and the trailer chassis system

- Application: Heavy goods vehicle traffic

- CAN-BUS data lines corresponding to the standard protocol according to ISO 11992-3

- Transmission of data not related to the chassis system

- Data lines seldomly used in practice

- Application: Agricultural technology

- CAN-BUS data lines corresponding to the standard protocol according to SAE J1939

- Guaranteed compatibility between tractor and implement independent of the manufacturer

New challenges in data transmission for commercial vehicles

Limits of the CAN-Bus technology

In the medium term, the connectors based on CAN-Bus will still be advanced to enable new services and functionalities. However, the question is if the current physical contact geometry and the serial CAN-Bus system developed in the 80s meet today's requirements.

A transmission rate of maximum 250 Kbit/s (for the standard SAE J1939) is considered a Low-Speed CAN-Bus. There also is a standard for a High-Speed CAN-Bus with a data transmission rate of up to 1 Mbit/s - but this Bus-System is not compatible with the Low-Speed-Bus and will not be able to meet future challenges as there are:

- Autonomous driving

- Real-time Control / High-Speed Data Exchange

- Big Data

- 360° view

Developments in the commercial vehicle industry

Economic requirements are a driver for innovation in the commercial vehicle industry. The trends are improved fleet management networks, which efficiently control commodity flows using real time data, the enhancement of road safety via 360° view and cyclist recognition and autonomous driving. These trends are enabled by the following functionalities.

For the enhancement of road and vehicle safety:

- A smart EBS stability program, a tire pressure monitoring system and the integration of axle load sensors into a networking system

- „Brake by Wire“ and „Steer by Wire“

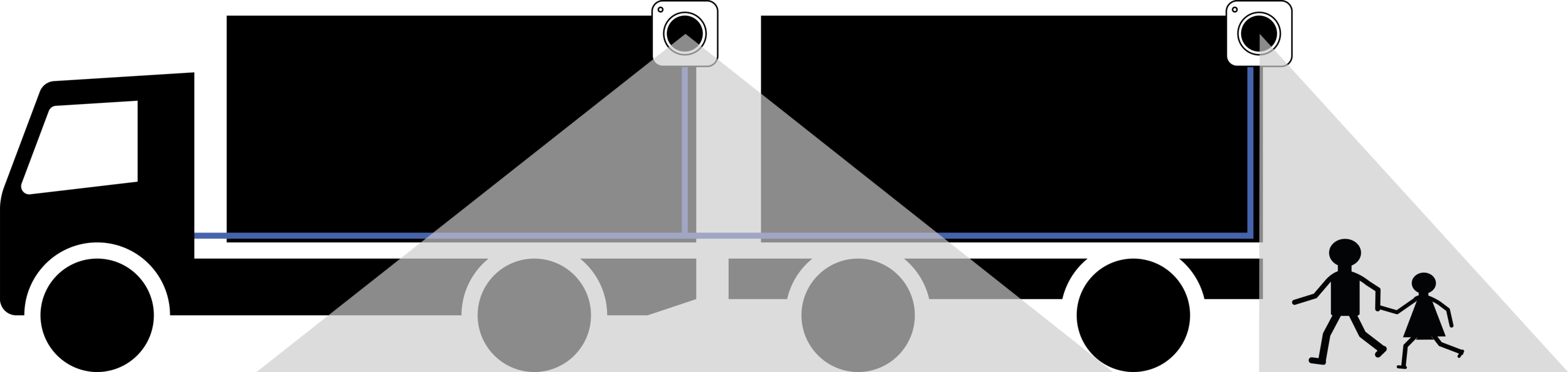

- 360° camera monitoring, freight hold monitoring and alarm sensors for the doors

- Integration of lidar and radar sensors as well as camera systems for supporting semi- or highly-automated driving functionalities

For the enhancement of comfort

- Traction aids with propelled trailer axes

- Monitoring and documentation of cold room temperatures

- Semi- or fully-automated coupling and uncoupling

- Interfaces and gateways for telematics applications and smartphone integration

For the enhancement of efficiency

- Electronic axes with recuperation

- Integration of new network-compatible sensors and actuators capable of auto-diagnosis for avoiding outages and calculating preventive maintenance for the trailer

Developments in the agricultural industry

Due to the continuous development of the network protocol according to SAE J1939 for CAN-Bus, this industry sector can be considered a pioneer. Tractors and implements are already interlinked quite well with the connections being constantly enhanced. However, there are also some future functionalities to be implemented:

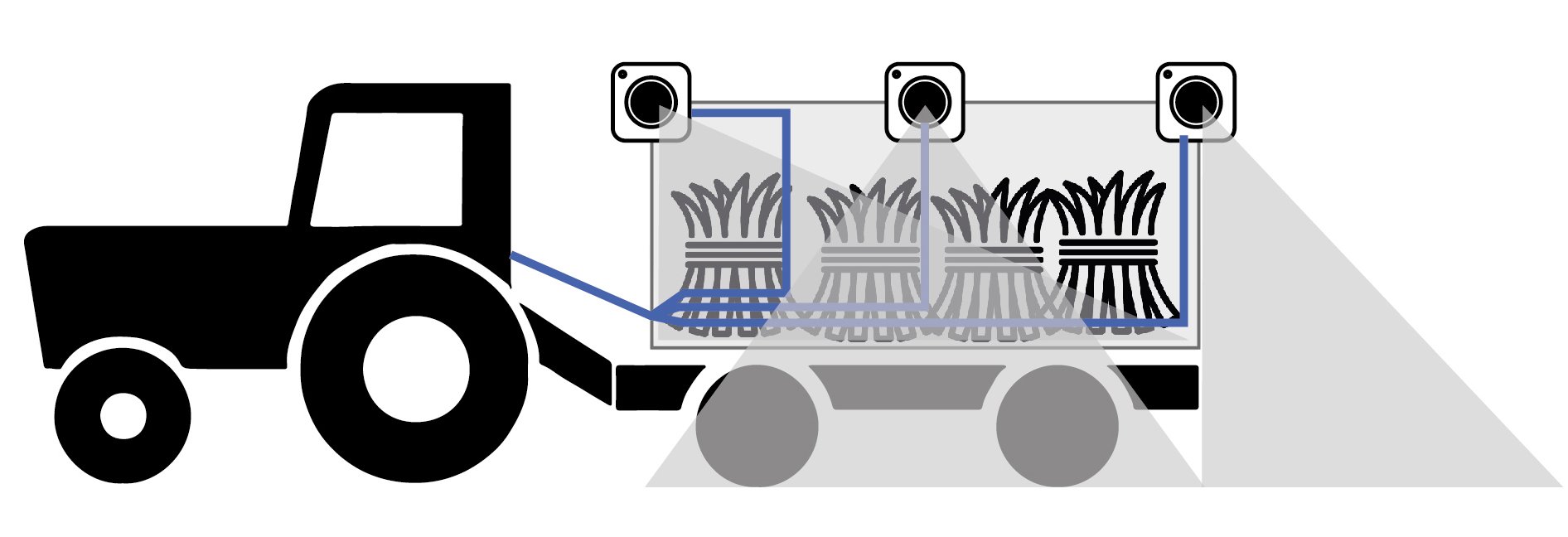

- Integration of a digital camera system - the current analog system is embedded in a parallel network. The goal is the digital processing of camera data for controlling highly automated planting and harvesting implements.

- Integration of all implements into a "Wireless Infiled Communication"-System enabling the real time and simultaneous coordination, coupling and control of various implements

Automotive Ethernet: Data transmission on the next level

All these developments require new functionalities and technologies that make high demands on the data transmission between trailer and towing vehicle. To meet these demands, new solutions for transmission routes and trailer connector networks are necessary. It is worthwhile to have a look at the automobile industry or, more precisely, at the concept of the Automotive Ethernet.

A new standard for data transmission

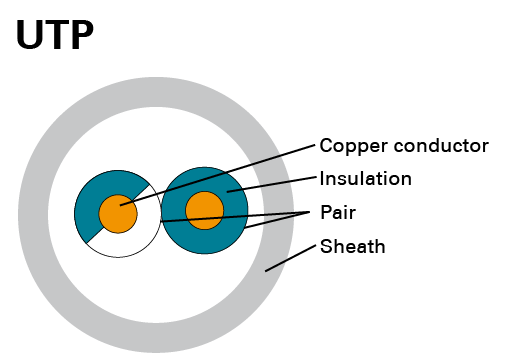

In 1983, the IEEE (Institute of Electrical and Electronics Engineers) standardized the ethernet technology for industrial engineering. Based on this, the IEEE developed a more economic version for the application in automobiles in the 2010s. The base of the system is an unshielded twisted cable - the so-called UTP (Unshielded Twisted Pair).

The transmission rate of the UTP cable is 100 Mbit/s. The transmission via one pair of wires is called 100BASE-T1. The IEEE defines this technology in the standard 802.3bw. With an unshielded cable, signals can be transferred over 15 m using the full-duplex system.

New solutions for more bandwidth

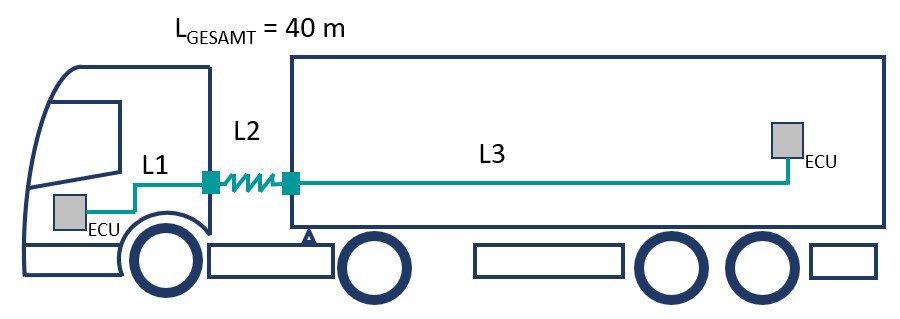

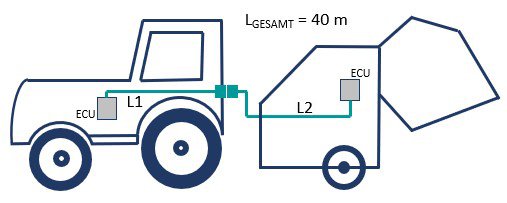

Considering heavy goods vehicle traffic and agricultural machinery, a cable length of at least 40 m is necessary. Apart from that, the given transmission rate of 100 Mbit/s still is insufficient for embedding data intensive applications such as cameras.

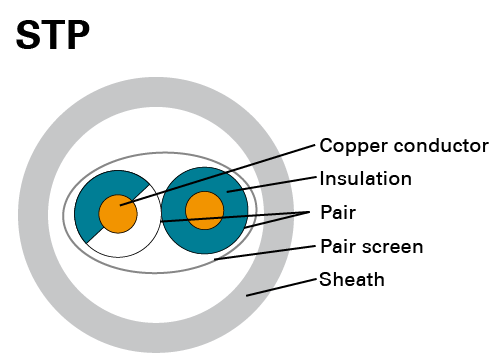

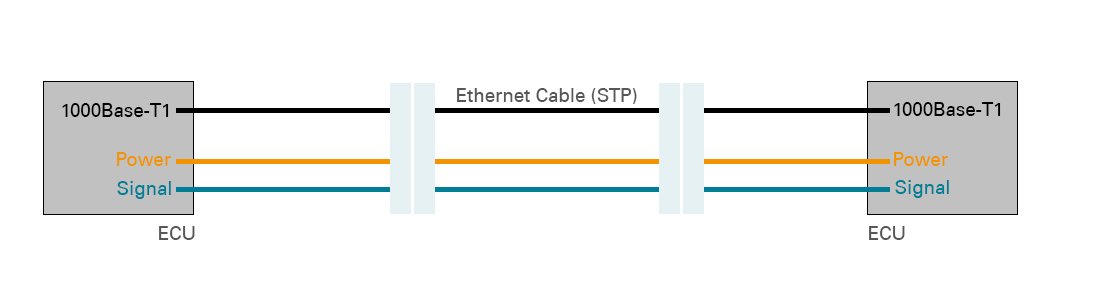

Considering these necessities, the new standard 1000BASE-T1 is very promising. With a bandwidth of 600 Mhz and a data transmission rate of 1 Gbit/s, the IEEE standard 802.3bp defines two lines: Type A with 15 m and an unshielded cable (UTP) and Type B with 40 m and a shielded cable (STP).

Solutions in data transmission for trucks and tractors with implements

Based on the Automotive Ethernet protocol with the standard 1000BASE-T1, ERICH JAEGER develops individually tailored future networking technologies for the commercial vehicle and agricultural industry. These include robust data connectors in combination with a 40 m STP cable. Therefore, the products fulfill both the requirement for a high data transmission rate (1 Gbit/s) and for a respective cable length.

Requirements for data connectors

Both the commercial vehicle and the agricultural industry make high demands on data connectors and cables:

- Extreme robustness and reliability in a harsh operation environment ranging from -40°C to +85°C

- High requirements on watertightness (IPX9K, IPX7)

- High number of connector operation cycles including several thousands of plug-ins over the complete life cycle

- Integration into a system corresponding to the highest safety requirements of automated driving functionalities with the highest safety level ASIL-D (Automotive Safetry Integrity Level)

- Application of robust hybrid cables for data and supply lines with high restoring forces for coils

- Functional safety at low temperatures in winter and at extreme heat due to high ambient and motor/gearing temperatures

- Backward compatibility

Prerequisites for a high bandwidth data transmission

The newly developed data line, which is integrated into a robust trailer connector housing, enables a higher data transmission rate of up to 1 Gbit/s thanks to its greater bandwidth.

The requirements are specified within the IEEE 802.3bp and the Open Alliance TC9.

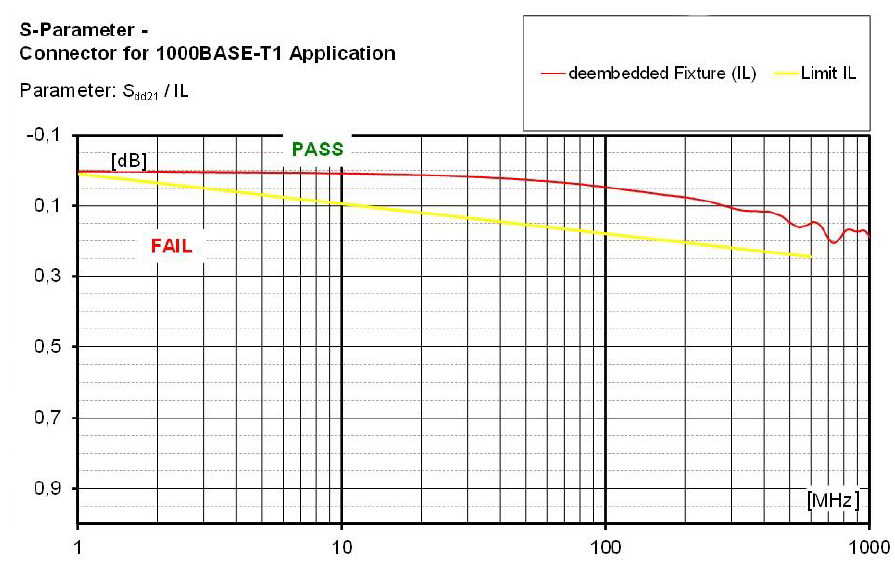

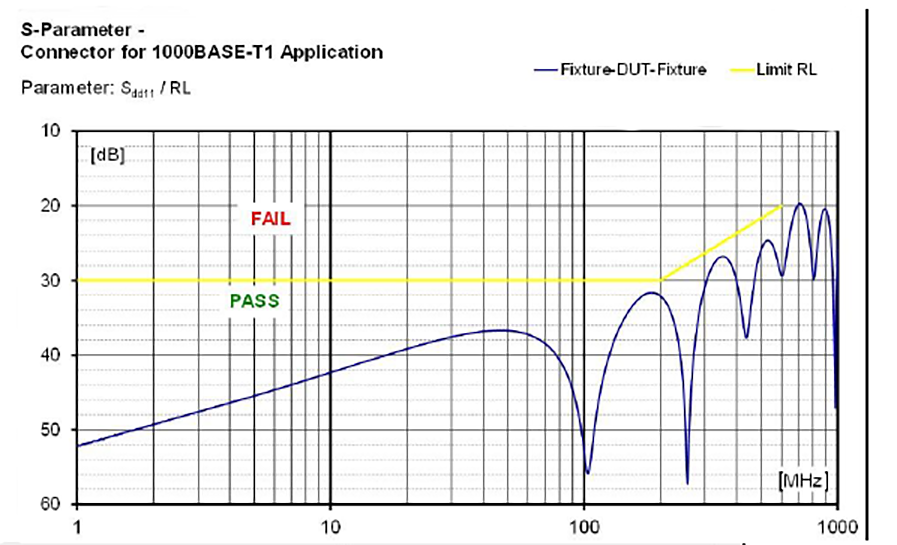

Two additional important parameters for the quality of a trailer connection Insertion Loss (IL) and Return Loss (RL) or reflection coefficient.

What is Insertion Loss?

The insertion loss is a ration expressed in decibel (dB). It describes the attenuation of the incident power (Pin) into a plug connection as a ration to the transmitted power (Pout).

IL (dB) = 10 Log10 Pin/Pout

The value of the insertion loss should be as low as possible.

In the two-port theory, the S-Parameters (scattering parameters) S12 and S21 are assigned to the insertion loss.

What is Return Loss?

The return loss is a ratio which is also expressed in decibel (dB). It describes the proportion of the incident power (Pi) towards the reflected power (Pr). It is an indication of quality for the calibration of cables and connectors. Return loss is commonly known as the reflection coefficient.

RL (dB) = 10 Log10 Pi/Pr

The value of the return loss should be as high as possible: the higher the value the lower the reflected power.

In the two-port theory, the S-Parameters (scattering parameters) S11 and S22 are assigned to the return loss.

Specific characteristics for the commercial vehicle industry

If the existing infrastructure is supposed to be replaced when introducing the new technology, backward compatibility is crucial.

At the moment, two electrical connectors are in use to control the brakes and the trailer lighting. A third connector could result in a lack of acceptance from the operator. The same may be true for a new type of connector which is not compatible to the current system. Therefore, compatibility to older vehicles and trailers is necessary.

The ERICH JAEGER connector is a hybrid connector which fulfills the requirements on the data communication according to 1000BASE-T1. At the same time, it provides further contact pairs for controlling different functionalities in the trailer. A connection to the old infrastructure is possible via an adapter.

The concept of the connector corresonds to the current technology, which meets the demands of the ADR for hazardous-cargo vehicles. The users are familiar with the components and the connection is watertight according to IP X9K both plugged in and out.

Specific characteristics for the agricultural industry

The agricultural industry is planning to introduce a new separate system architecture to open up new application possibilities with a small and compact data connector. Moreover, the new data connector supports the Break-Away requirement which is already fulfilled by ERICH JAEGER's ISOBUS connectors according to ISO 11783-2. The connectors are tested according to SAE/USCAR-2 and are watertight according to IP 6K9K and IP 67. Considering these features, the system is more than fit to be used with the demanding applications and harsh environmental conditions in agricultural industry.