Content

Towbars and automobile trailer devices – the story so far

Electrical connection of the trailer

When electrical signals were first exchanged between the on-board vehicle system and the trailer in the trailer industry, it was all pretty straightforward: flasher unit communication was sufficient to ensure the trailer turn signals were functioning correctly for the driver. Control of the flasher units on the vehicle side was later taken over by other control systems in the vehicle. Simple flasher unit communication was thus no longer possible. ERICH JAEGER then developed a new control unit under the name JAEGERTRONIC®. This tells the on-board system control units when there is a turn signal fault in the trailer.

Following the expansion of the CAN-BUS (Controller Area Network) architecture to all German manufacturers and subsequently also to importers, ERICH JAEGER developed control units that communicate reliably with the vehicle via the corresponding CAN protocol. The “JaegerCANtrol®” trailer control devices read all the data required via a 2-cable CAN-BUS. Communication is by high-speed bus at a speed of up to 1 Mbit/s.

The control unit is integrated into the vehicle bus so that it is bi-directional and can be set up, usually in a contracted workshop, to use other convenience functions (trailer ESP, for example, and PDC switch-off).

Development of trailer towbars

In Europe, automobile trailers are towed by a coupling head. The first patent for this dates back to March 14, 1934. It describes a towbar for motor vehicles with an overrun brake on the trailer and a self-actuating switching device for the trailer tail light.

The trailer towing device is a fixed ball-head bar firmly fixed mechanically to the vehicle body by a bracket.

Detachable towbar

The so-called detachable trailer towbar was subsequently launched on the market for aesthetic reasons. This allows the user to fit the ball-head rod vertically in a holder that is part of a secure locking system. This is fitted to a bracket behind the fender. When the trailer is not required, the connector can be removed (here, an example made by Brink). Correct locking and unlocking is indicated by green and red markings.

Retractable towbar

The next level of convenience is represented by a towbar that swivels manually. This avoids having to carry the ball-head bar around as a dirty spare part in the vehicle. The bar can be swiveled mechanically between resting and working positions (here, an example made by Brink).

Up to this point in the development of the coupling, secure locking is purely mechanical, as is the display of confirmation of locking. Electrification of actuation, locking and display through to automatic swivel trailer connection are features that bring even greater convenience with them. For that degree of automation, however, vehicle manufacturers and retrofitting companies must integrate the complete system deep into the vehicle’s digital infrastructure.

Requirements of control units for electric swiveling tow bars

With a semi-electric swiveling towbar, the user presses a push button, which unlocks the ball-head rod. A visual or acoustic signal indicates whether the system is retracted or ready to use and correctly engaged. With a fully electric swiveling towbar, all the functions, including unlocking, swiveling of the bar into place and locking, are carried out automatically in the correct sequence via a switch, which is usually fitted in the trunk.

When it comes to developing and producing vehicle components, the rule is always to meet the requirements of the latest technology. What does this mean for further development?

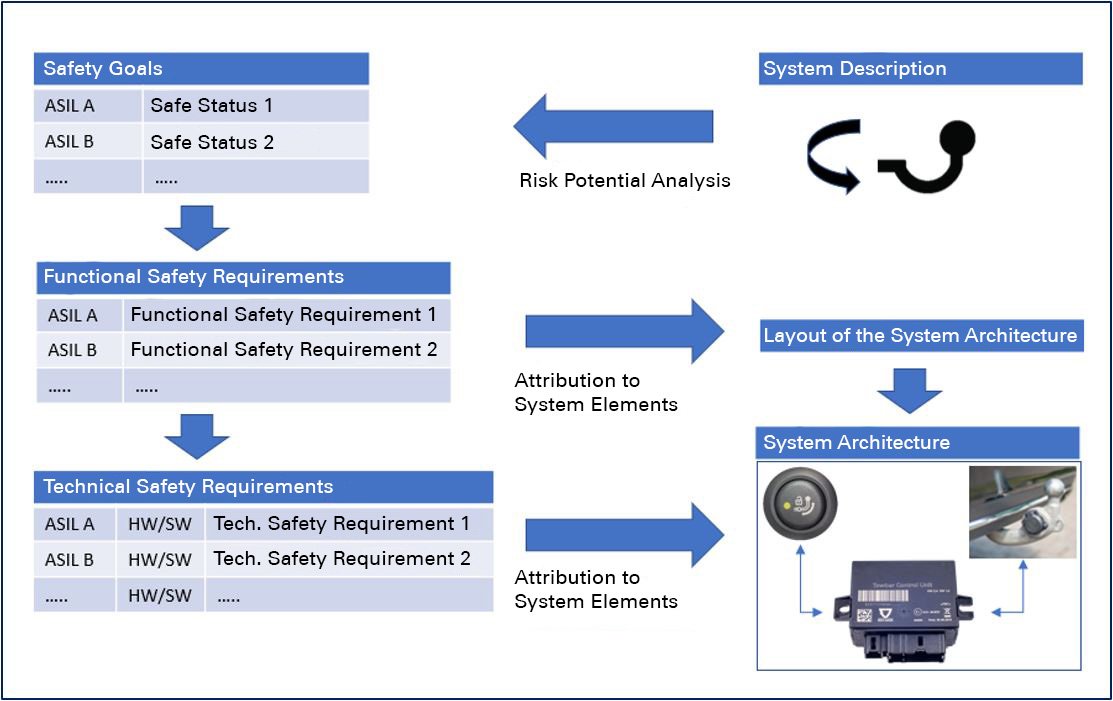

Vehicle control units according to ISO 26262

As a result of the electrification of the towbar, the new control units are covered by the ISO standard on functional safety, which is still very new. ISO 26262 Road Vehicles – Functional Safety defines a procedural model for the development of safety-related electrical/electronic systems in motor vehicles. The aim is to avoid or detect any faults in the hardware, software and system and to put a potential fault into a so-called “safe state” – a pre-defined condition of the system as a whole that minimizes the potential risks to users.

The most common patterns of faults include the towbar swinging out unintentionally while driving, defective status and operating information and an unplanned swivel operation while the vehicle is stationary, with the potential risk of injury.

Classification according to the ASIL

Following analysis of the potential risks that could come from the new product, classification is carried out according to the ASIL (Automotive Safety Integrity Level). Following definition of the safety objectives, the new functional safety requirements for the hardware and software in the new system are established, followed by the technical safety requirements.

Other requirements

Other directives and standards must be observed in the development process to meet the safety requirements for hardware, software and system design:

- MISRA C:2012:

Guidelines for programming in critical systems - HIS Source Code Metrics:

Standard for software design - IEC 61709:2017:

Reliability of hardware components - ISO/PAS 21448:

Safety of the intended system functionality

ERICH JAEGER aligns its processes consistently with the requirements

For ERICH JAEGER, this means organizing the process landscape to meet those requirements. That begins as soon as development starts and ends only at the end of life (EOL).

Development of the software conforms to the Automotive SPICE model (latest version 3.1). This qualifies ERICH JAEGER as a control unit supplier to the automobile industry.

Last but not least: To meet and comply with all of the defined quality features, the products are covered by a process-based approach to company procedures, from development through to production, in accordance with the IATF 16949:2016 standard.

The control unit for swiveling towbars from ERICH JAEGER

Of course, all the considerations regarding implementation of ISO 26262 for vehicle control units are based on a specific application: the company’s engineers created a control unit for swiveling towbars on behalf of a large automobile manufacturer. In accordance with the ISO standard on functional safety, the module was classified under the ASIL system for assessment of safety risks. In this regard, it corresponds to ASIL B.

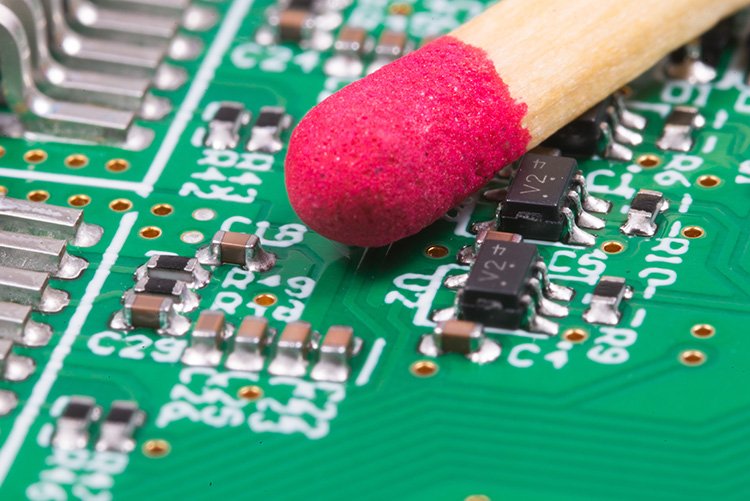

Product improvements for the housing and electronics

In addition, the team from ERICH JAEGER has been able to bring about further improvements for both modules:

- The PBT housing material enhances the structural integrity of the housing and its resistance to environmental factors

- A recently developed double-plug connector combines standard 16- and 8-pin plug connectors in just one component and brings cost benefits and a reduction in the force required to fit the plug

- Cost-effective micro-components on the circuit board provide a very low quiescent current of approx. 30 μA

- A QR code on the circuit board and housing ensures traceability of the control units